services & capabilities

Discover our professional metal finishing solutions, designed to deliver precision, durability, and reliability for a wide range of industries and applications.

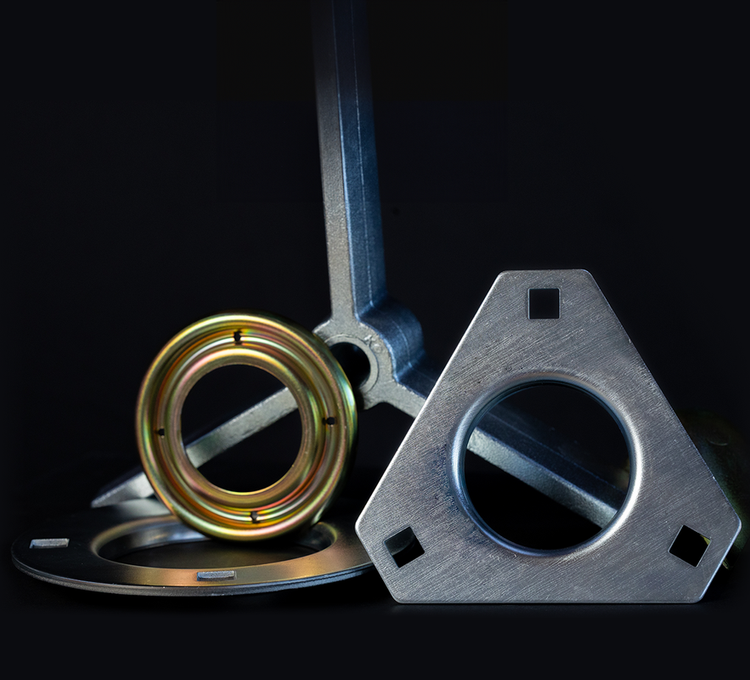

High-Quality Metal Finishing Solutions

At The Bass Plating Company, we provide reliable and precise metal finishing designed to enhance strength, performance, and appearance. With years of expertise and advanced processes, we deliver consistent results tailored to meet industry standards and customer needs.

Zinc Plating

Zinc plating provides a protective coating that enhances corrosion resistance and extends the lifespan of metal components. Ideal for a variety of industries, this finish offers a durable, cost-effective solution for preventing rust and wear.

Tin Plating

Tin plating provides a smooth, conductive, and corrosion-resistant finish, making it ideal for electrical components and food-safe applications. This coating enhances solderability, reduces wear, and protects against oxidation in demanding environments.

Chemical Films

Chemical films provide a protective conversion coating that enhances corrosion resistance and adhesion for paints or adhesives. This process is commonly used on aluminum surfaces to improve durability while maintaining conductivity.

Aluminum Anodizing

Aluminum anodizing enhances the surface of aluminum parts by increasing corrosion resistance, durability, and wear protection. This process also allows for improved adhesion of paints and coatings, making it ideal for various industrial applications.

Aluminum Etching

Aluminum etching removes surface contaminants and creates a uniform texture, improving adhesion for coatings and enhancing corrosion resistance. This process is ideal for preparing aluminum components for finishing while maintaining precision and consistency.

Large part? no problem

Bass Plating specializes in handling large and heavy metal components with precision and care. Our facility is equipped to plate oversized parts that other shops often can’t accommodate—without sacrificing quality or turnaround time. With extensive rack plating expertise and custom setups, we ensure consistent coverage and finish, even on complex geometries. Whether it's telecom cabinets, industrial enclosures, or structural elements, we’re built for big jobs.

industries we serve

At Bass Plating, we proudly serve a diverse range of industries that rely on high-quality metal finishing for durability, corrosion resistance, and performance. From automotive components that require superior protection against wear and tear to aerospace parts that demand precision and reliability, our expertise ensures top-tier results. We also support the electrical industry with coatings that enhance conductivity and longevity, as well as industrial and manufacturing sectors.

frequently asked questions

What metal finishing services does Bass Plating offer?

We provide a range of metal finishing services, including plating, anodizing, etching, and chemical films. Our processes are designed to enhance durability, corrosion resistance, and performance across various industries.

Can you handle high-volume production?

Yes, our facility is equipped with 7 automated rack lines and 3 automated barrel lines, allowing us to efficiently process large-volume orders while maintaining consistent quality.

Do you offer plating for large parts?

Absolutely. We specialize in plating large-sized components, with the capability to process parts up to the size of a phone booth, making us ideal for industrial and heavy-duty applications.

Are your finishing processes compliant with industry regulations?

Yes, we offer ROHS-compliant plating options and adhere to strict industry standards to ensure high-quality, environmentally responsible metal finishing solutions.